Titanium's ogbenye thermal conductivity na elu chemical reactivity na-eme ka ọ na-adịkarị mfe n'elu ntụpọ n'ogeCNC igwe. Ọ bụ ezie na a na-enyocha geometry ngwá ọrụ na akụkụ ịkpụ nke ọma, njikarịcha oyi ka ejighị n'aka na omume ụlọ ọrụ. Ọmụmụ ihe a (emere na 2025) na-eleba anya ọdịiche a site n'ịkọpụta ka nnyefe coolant ezubere iche si eme ka mma ngwụcha na-emebi emebi.

Usoro

1. Nleba anya

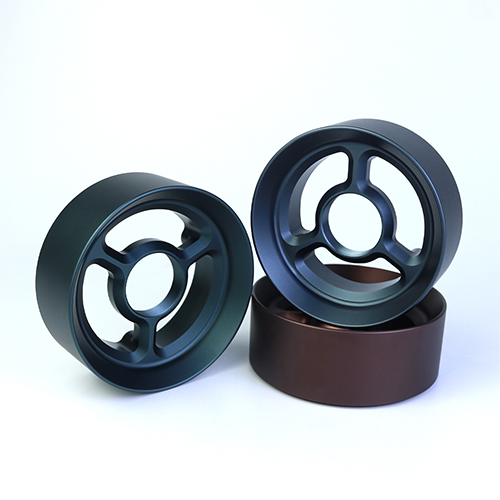

●Ihe:Ogwe Ti-6Al-4V (Ø50mm)

●Ngwa:5-axis CNC nwere ikuku oyi na-arụ ọrụ (oke nrụgide: 20-100 mmanya)

●Esochiri metric:

Ịdị ike dị n'elu (Ra) site na kọntaktị profaịlụ

Ngwá ọrụ flank yi na-eji USB microscope imaging

Okpomọkụ mpaghara ịkpụ (FLIR igwefoto ọkụ)

2. Njikwa ugboro ugboro

●Nlegharị ule atọ n'otu n'otu n'otu nkeji

● A na-edochi ihe ntinye ngwaọrụ mgbe nnwale ọ bụla gasịrị

● Ambient okpomọkụ kwadoro na 22°C ±1°C

Nsonaazụ & Nyocha

1. Coolant Nrụgide vs. Elu mechaa

●Nrụgide (ụlọ mmanya):20 50 80

●Nkeji Ra (μm) :3.2 2.1 1.4

●Uwe Ngwá Ọrụ (mm):0,28 0,19 0,12

Igwe nju oyi dị elu (ogwe 80) belatara Ra site na 56% na ntọala (ogwe 20).

2. Mmetụta Ndozi Nozzle

Nozzles nwere akụkụ (15° n'ọnụ ọnụ ngwá ọrụ) rụpụtara nhazi radial site na:

● Na-ebelata mkpokọta okpomọkụ site na 27% (data thermal)

● Na-agbatị ndụ ngwá ọrụ site na 30% (ntụgharị uwe)

Mkparịta ụka

1. Ụzọ isi

●Mwepu mgbawa:Igwe oyi dị elu na-agbaji ibe dị ogologo, na-egbochi ịkpụgharị ọzọ.

●Njikwa okpomọkụ:Njụjụ dị n'ime mpaghara na-ebelata mgbagha workpiece.

2. Oke bara uru

● Achọrọ ntọala CNC gbanwetụrụ (ikike mgbapụta mmanya kacha nta 50)

● Ọ bụghị ọnụ ala maka mmepụta obere olu

Mmechi

Ịmepụta nrụgide coolant na nhazi nozzle na-eme ka ọ dị mma imecha elu titanium. Ndị nrụpụta kwesịrị ibute ụzọ:

●Nkwalite na ≥80 bar coolant sistem

● Na-eme nnwale n'ọkwa nozzle maka ngwa ọrụ akọwapụtara

Nnyocha ọzọ kwesịrị inyocha ngwakọ jụrụ oyi (dịka, cryogenic+MQL) maka alloys siri ike na-arụ ọrụ.

Oge nzipu: Ọgọst-01-2025