PFT, Shenzhen

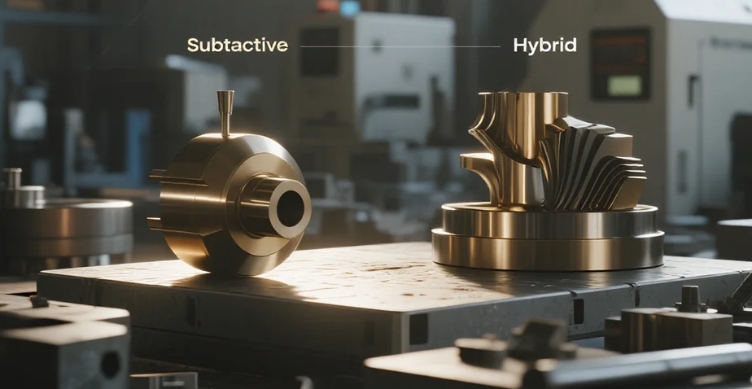

Ọmụmụ ihe a na-atụnyere ịdị irè nke CNC machining subtractive omenala na-emepụta ngwakọ CNC-Additive Manufacturing (AM) maka ịrụzi ngwá ọrụ mmepụta ihe. A na-agbakọ metrik arụmọrụ (oge nrụzi, oriri ihe, ike igwe) site na iji nnwale a na-achịkwa na ọnwụ stampụ mebiri emebi. Nsonaazụ na-egosi na ụzọ ngwakọ na-ebelata ihe mkpofu ihe site na 28-42% wee mee ka usoro nrụzi dị mkpụmkpụ site na 15-30% na nsonazụ mwepu-naanị. Nyocha microstructural na-akwado ike tensile yiri (≥98% nke ngwa ọrụ mbụ) na ngwakọ emeziri. Mmachi bụ isi gụnyere mmachi mgbagwoju anya geometric maka ntinye AM. Nchọpụta ndị a na-egosi ngwakọ CNC-AM dị ka atụmatụ bara uru maka nlekọta ngwá ọrụ na-adigide.

1 Okwu mmalite

Mmebi akụrụngwa na-efu ụlọ ọrụ nrụpụta $240B kwa afọ (NIST, 2024). Ndozi CNC mwepu ọdịnala na-ewepụ akụkụ ndị mebiri emebi site na igwe igwe/egweri, na-atụfukarị> 60% nke ihe nwere ike ịzọpụta. Ngwakọta CNC-AM ngwakọ (nkwado ike ozugbo na ngwaọrụ dị adị) na-ekwe nkwa ịrụ ọrụ akụrụngwa mana enweghị nkwado ụlọ ọrụ. Nke a nnyocha quantifies arụmọrụ uru nke ngwakọ workflows vesos ot subtractive ụzọ maka elu-uru tooling ịrụkwa.

2 Usoro

2.1 Nleba anya

H13 ígwè stamping ise mebiri emebi na-anwụ (akụkụ: 300 × 150 × 80mm) mere usoro nrụzi abụọ:

-

Otu A (Mwepụ):

- Mwepụ mmebi site na igwe igwe 5-axis (DMG MORI DMU 80)

- Nkwụnye ego ịgbado ọkụ (GTAW)

- Mechaa machining na CAD mbụ -

Otu B (ngwakọ):

- Mwepụ ntụpọ pere mpe (<1mm omimi)

- Nrụzi DED site na iji Meltio M450 (waya 316L)

- Nrụgharị CNC na-agbanwe agbanwe (Siemens NX CAM)

2.2 Nweta data

-

Ịrụ ọrụ ihe: Ntụle Mass tupu/mmezi mmezi (Mettler XS205)

-

Ndepụta oge: Nyochaa usoro na ihe mmetụta IoT (ToolConnect)

-

Nnwale igwe:

- Maapụ ike (Buehler IndentaMet 1100)

- Ihe nlere anya (ASTM E8 / E8M) sitere na mpaghara arụziri

3 Nsonaazụ & Nyocha

3.1 Iji akụrụngwa

Tebụl 1: Ntụle Metrics Usoro Mmezi

| Metric | Mmezi Mwepu | Mmezi ngwakọ | Mbelata |

|---|---|---|---|

| Ihe oriri | 1,850g ± 120g | 1,080g ± 90g | 41.6% |

| Oge mmezi arụ ọrụ | 14.2 elekere ± 1.1 elekere | 10.1 elekere ± 0.8 elekere | 28.9% |

| Ojiji ike | 38.7 kWh ± 2.4 kWh | 29.5 kWh ± 1.9 kWh | 23.8% |

3.2 Mechanical iguzosi ike n'ezi ihe

Egosipụtara ụdịdị ngwakọ emeziri:

-

Isi ike na-agbanwe agbanwe (52–54 HRC vs. mbụ 53 HRC)

-

Ike ike kachasị elu: 1,890 MPa (± 25 MPa) - 98.4% nke ihe ndabere.

-

Enweghị delamination interface na ule ike ọgwụgwụ (10⁶ cycles na 80% na-enye nrụgide)

Ọgụgụ 1: Microstructure nke ngwakọ nrụzi interface (SEM 500×)

Mara: Nhazi ọka gbakọtara na oke njikọ na-egosi njikwa ọkụ dị mma.

4 Mkparịta ụka

4.1 Mmetụta arụmọrụ

Mbelata oge 28.9% sitere na iwepụ nnukwu ihe onwunwe. Nhazi ngwakọ na-egosi uru maka:

-

Ngwa ihe nketa nwere ngwaahịa ihe kwụsịrị

-

Geometries nwere mgbagwoju anya dị elu (dịka ọmụmaatụ, ọwa jụrụ oyi)

-

Ọnọdụ nrụzi obere olu

4.2 Mgbochi teknụzụ

Achọpụtara oke:

-

Akụkụ nkwụnye ego kacha elu: 45° site na kehoraizin (na-egbochi ntụpọ nfefe)

-

Ọdịiche ọkpụrụkpụ nke oyi akwa DED: ± 0.12mm chọrọ ụzọ ngwaọrụ mmegharị

-

Usoro ọgwụgwọ HIP na-aga n'ihu dị mkpa maka ngwaọrụ ọkwa ikuku

5 Nkwubi okwu

Ngwakọ CNC-AM na-ebelata oriri akụrụngwa nrụzi ngwá ọrụ site na 23-42% ebe ọ na-edobe nha nhata n'ibu na ụzọ mwepu. A na-atụ aro itinye n'ọrụ maka akụrụngwa nwere mgbagwoju anya geometric na-agafeghị oke ebe nchekwa ihe na-akwado ụgwọ ọrụ AM. Nchọpụta na-esote ga-ebuli atụmatụ nkwụnye ego maka ígwè ọrụ siri ike (> 60 HRC).

Oge nzipu: Ọgọst-04-2025